Choosing the right powder coating to use may seem simple. However, by providing the powder coating supplier with a detailed description of how the powder coating you need will work on the pieces, you will ensure the smooth final quality of your products.

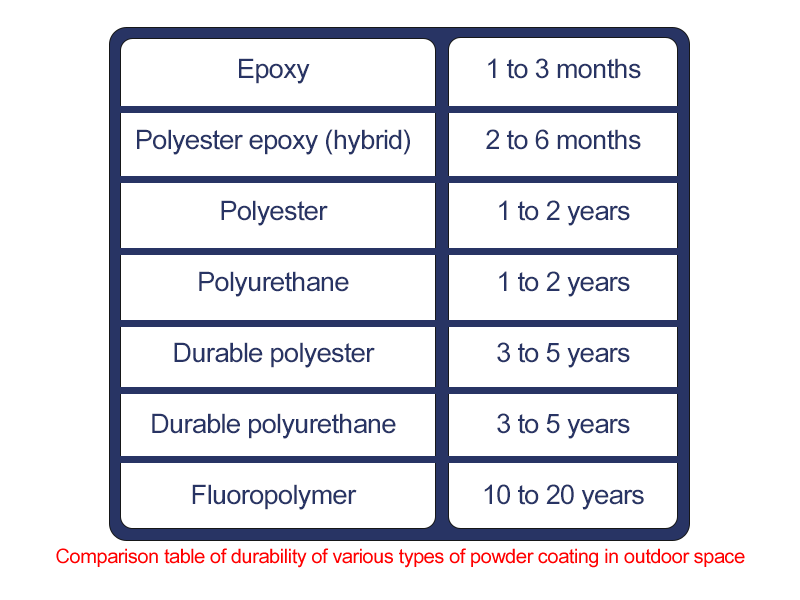

The first feature to consider when choosing the right powder coating is whether the coating will be exposed to sunlight or not.

Powder coatings as a single-layer coating have relatively good resistance to corrosion compared to most liquid coatings, it is said that not only is it important to ensure high surface quality and proper preparation, but it is recommended to use a two-layer coating system for highly corrosive environments, combining a high-quality epoxy primer with durable, UV-resistant coatings can provide the most ideal coverage, epoxies have the best corrosion resistance, but they degrade and eventually wear out when exposed to sunlight, hence, they perform well in indoor environments or when used on buried surfaces, for example oil and gas pipes, in general, hybrids and polyurethanes have very good resistance to corrosion on well-prepared surfaces. Polyurethanes also have the double advantage of good resistance to ultraviolet rays.

Resistance to chemical stains is one of the important criteria that you should consider when choosing the right powder coating, resistance to cleaners, disinfectants and polishing compounds is an obvious requirement for most powder coatings, in addition, more specific requirements such as resistance to fingerprints, food, lubricating oils, sealants, solvents, mortars, fuels, and hydraulic oils may be an important feature for powder coating, sharing your expected characteristics with the powder coating unit of Rangin Kimia Company will help to provide a powder coating with acceptable performance in terms of chemical stain resistance, epoxies and polyurethanes are the best choice for applications where chemical stain resistance is required.

For products coated with powder coating that are used repeatedly, durability of the surface is required. Surface strength can be defined as hardness or resistance to wear and scratches. These characteristics are slightly different, so determining a specific characteristic for all of them can be a challenge.

The hardness of a powder coating creates a solid surface, however, hardness alone may not be sufficient for this purpose, sometimes the level of surface slip or a low coefficient of friction is also necessary. Powder coating formulations can provide a powder to create a slippery surface, which may meet this need.

Mechanical flexibility is an important property. Typically, epoxies, hybrids (epoxy polyester) and polyesters have excellent flexibility and are impact resistant.

Of course, appearance features are very important for most applications. Color is created by pigments that are formulated into powder coating, it is important to determine the lighting conditions that your product will be exposed to because powder coatings can look perfectly acceptable with one light source but not with another, and not only should they be described with high quality criteria, acid cure glossy or matte, but its amount should be defined in a certain glossiness range, see the table below. The amount of glossiness is measured using a glossiness meter and this device can be obtained from the supplier of laboratory equipment. These devices can measure the glossiness in two or three different angles depending on the instruments that measure its glossiness. The glossiness measurement unit is GU.

Also, according to the type and uses of the piece in question, you can choose from colors with a patterned surface such as leather, hammer, and granite, sanded and decorative colors. Rangin Kimia powder coating unit has been able to satisfy the needs and tastes of customers by producing a wide range of these products.

Production and collection: Rangin Kimia Industrial Complex

All rights of this article are reserved for Rangin Kimia.