Powder coatings in the world were produced for the first time in 1950 in the United States of America, at that time, the epoxy resin along with the curing agent, pigments, and color flow agent, all of which are solid, were mixed with one another in a mixer, and then ground, and the resulting powder was applied to the parts using the fluid bed method, and it was sent to the oven for final heating.

In 1962, the electrostatic spray gun method for spraying powder coating was invented for the first time.At present, powder colors are widely produced based on different resins and are widely used in various industries.

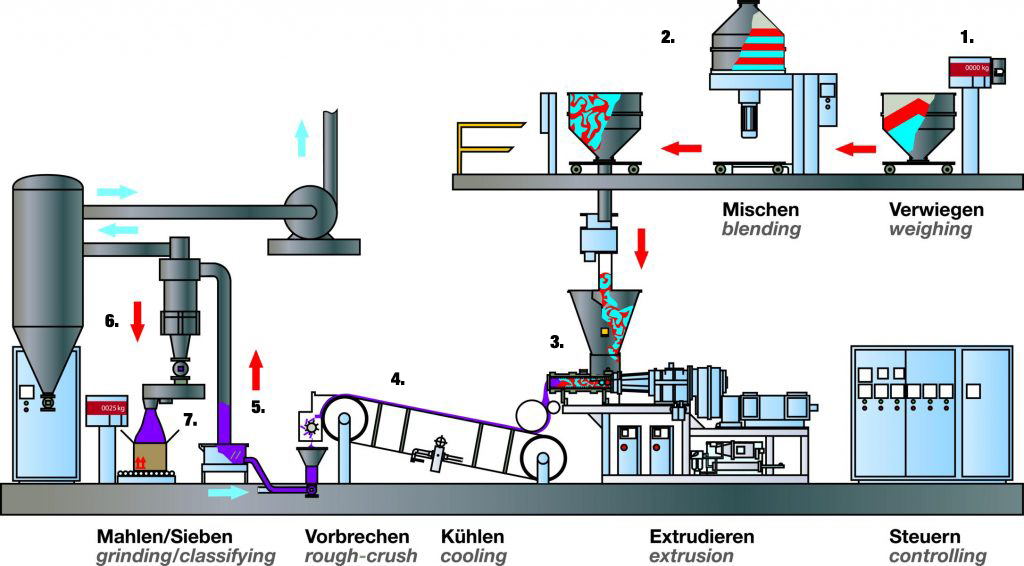

Powder coating is produced from the combination of resin, filler, pigment and additives, and the raw materials are in solid form, these materials are mixed with each other in molten form and become solid (powder) again.

In a powder coating formula, choosing the right resin is the most important principle because the resin determines the overall performance of the coating, and additives, fillers and pigments, prepares the resin for the desired color and specifications such as curing speed, viscosity, etc. There are different types of resin for powder coating formulas with different properties, each of which is suitable for a specific purpose.

These coatings are based on carboxylated polyester resin and are formed by chemical reaction between polyester resin and an active curing agent, this coating has a very good resistance to sunlight and for this purpose it is used for outdoor applications such as aluminum profile industries, bicycles and motorcycles, heating and air conditioning systems, construction industry and park equipment.

Due to the presence of epoxy resin in their base, these coatings tend to become chalky against sunlight (UV rays), and they don’t have good resistance in the open space, so these coatings are generally used for indoor applications such as household appliances, radiators, electrical components, metal office equipment and shelves.

These coatings are formed by the reaction of epoxy resin and a crosslinking agent, and they have excellent chemical and corrosion resistance and good mechanical properties, but they tend to become chalky when exposed to sunlight, due to the good adhesion properties and cathodic separation property of epoxy coatings, this type of coating is used in the coating of water connection valves of oil and gas pipes, today, it is used for multi-layer coatings, which is the type of Fusion Bonded Epoxy.

Polyurethane powder coatings are another type of powder coatings that are obtained from the combination of polyester resins and isocyanate curing agent. The properties of these colors can be mentioned as very high weather resistance, especially for covering marine equipment.

It is mostly used for top coat of car parts and luxury wheel rims.

These coatings have a very high final quality and in comparison, they have a very high price and are used for the construction industry with epoxy primer.

One of the best services for customers is choosing the right resin in the formula of powder coatings according to the purpose of specific use, because it is very enjoyable to produce a product that meets their needs well.

Production and collection: Rangin Kimia Industrial Complex

All rights of this article are reserved for Rangin Kimia.